Top Challenge: Balancing Aesthetics with Durability and Efficiency Architects and specification writers often struggle to find cladding materials that do not…

Top Challenge: Balancing Aesthetics with Durability and Efficiency Architects and specification writers often struggle to find cladding materials that do not…

Click Here To Read The Full Article

Knotwood soffits are more than just a finishing touch for your home – they offer a blend of style and…

Click Here To Read The Full Article

In the lofty heights of mountainous regions, zinc roofs have become a common sight. As you ascend, zinc becomes the…

Click Here To Read The Full Article

Setting the Stage: The Moody Center's Grand Debut In the heart of Austin, the Moody Center emerged as a beacon of…

Click Here To Read The Full Article

Elevating Las Vegas with CityCenter Las Vegas in the U.S. state of Nevada, known for its constant pursuit of bigger, brighter,…

Click Here To Read The Full Article

elZinc® is a premium product, irrespective of its final application. The expectation is to achieve, in terms of product and service,…

Click Here To Read The Full Article

Sustainable building envelopes have long been at the forefront of construction innovation, with a primary focus on reducing heat loss…

Click Here To Read The Full Article

Crafted by John Wardle Architects, Curtin University's School of Design and the Built Environment (DBE) boasts a cutting-edge design in…

Click Here To Read The Full Article

elZinc is excited to announce the launch of one of the largest photovoltaic plants in Asturias, Spain. This solar generation…

Click Here To Read The Full Article

elZinc and MAZZONETTO have jointly announced a new distribution partnership for the Italian market. A distribution agreement has been formalized…

Click Here To Read The Full Article

elZinc, a renowned brand in the world of high-quality zinc products, is delighted to announce that it has secured the…

Click Here To Read The Full Article

Roofing materials are always a popular topic in Canada, and for good reason. Specifiers in the Great White North are…

Click Here To Read The Full Article

The construction of a new entrance, cycle hub and platform canopies at a popular south London train station is being…

Click Here To Read The Full Article

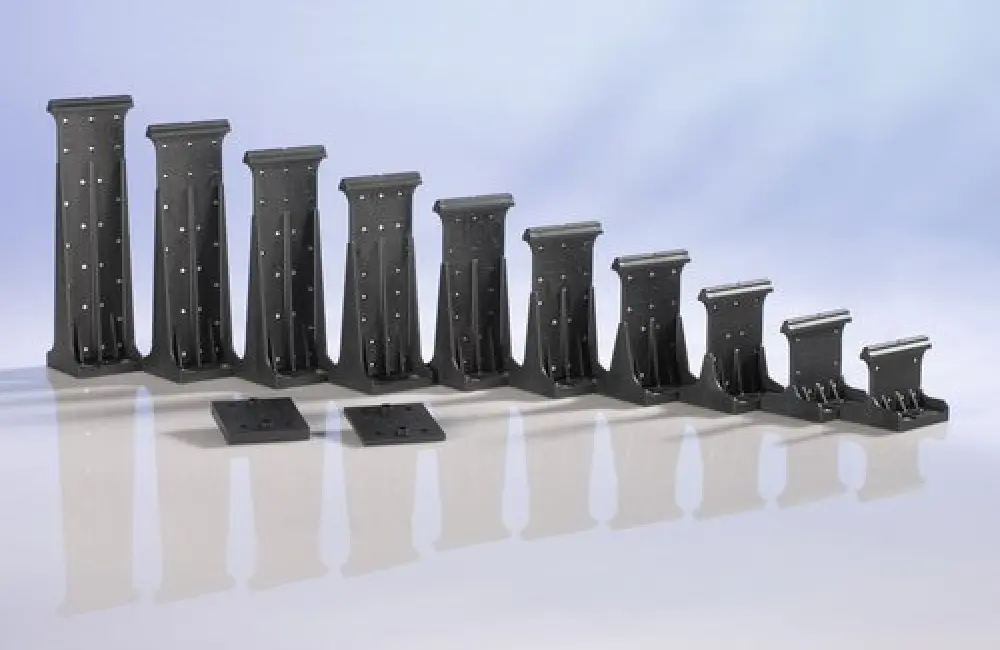

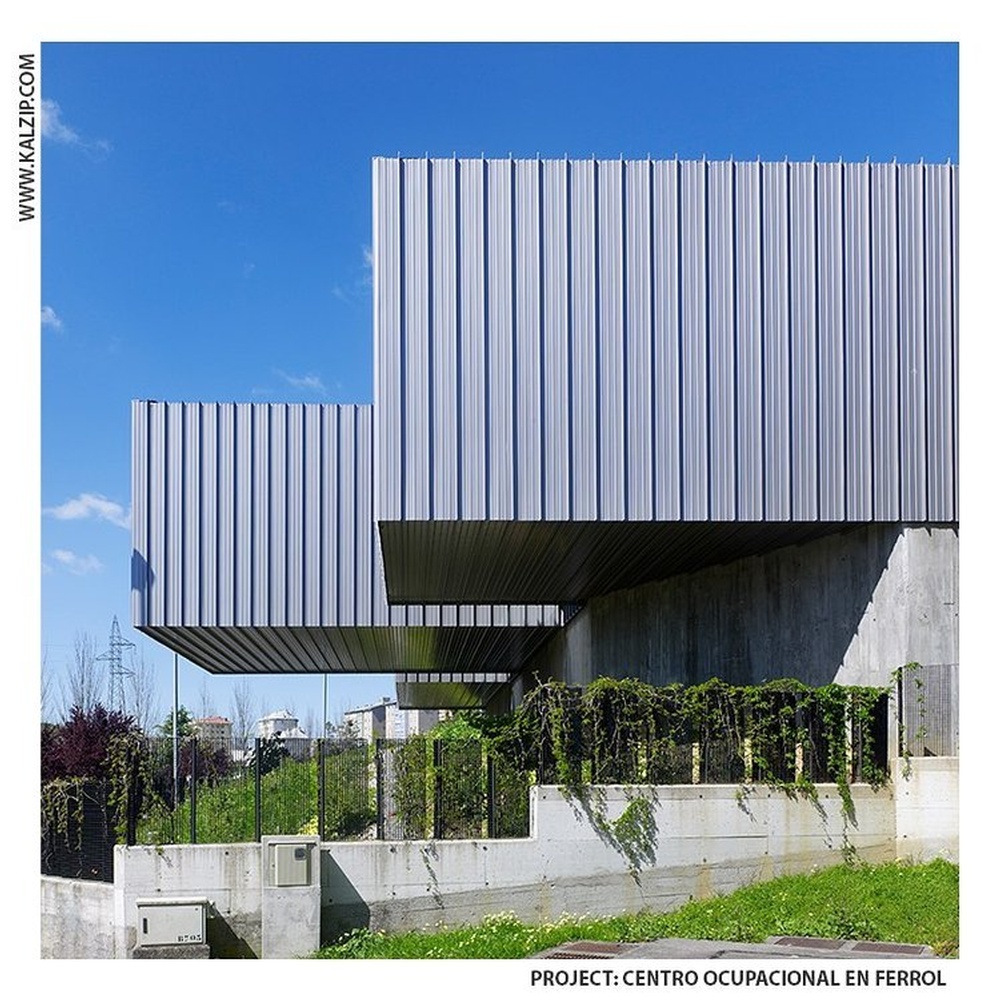

Kalzip is well known for their Roof and facades products made of Aluminium. In most cases, the products are used…

Click Here To Read The Full Article

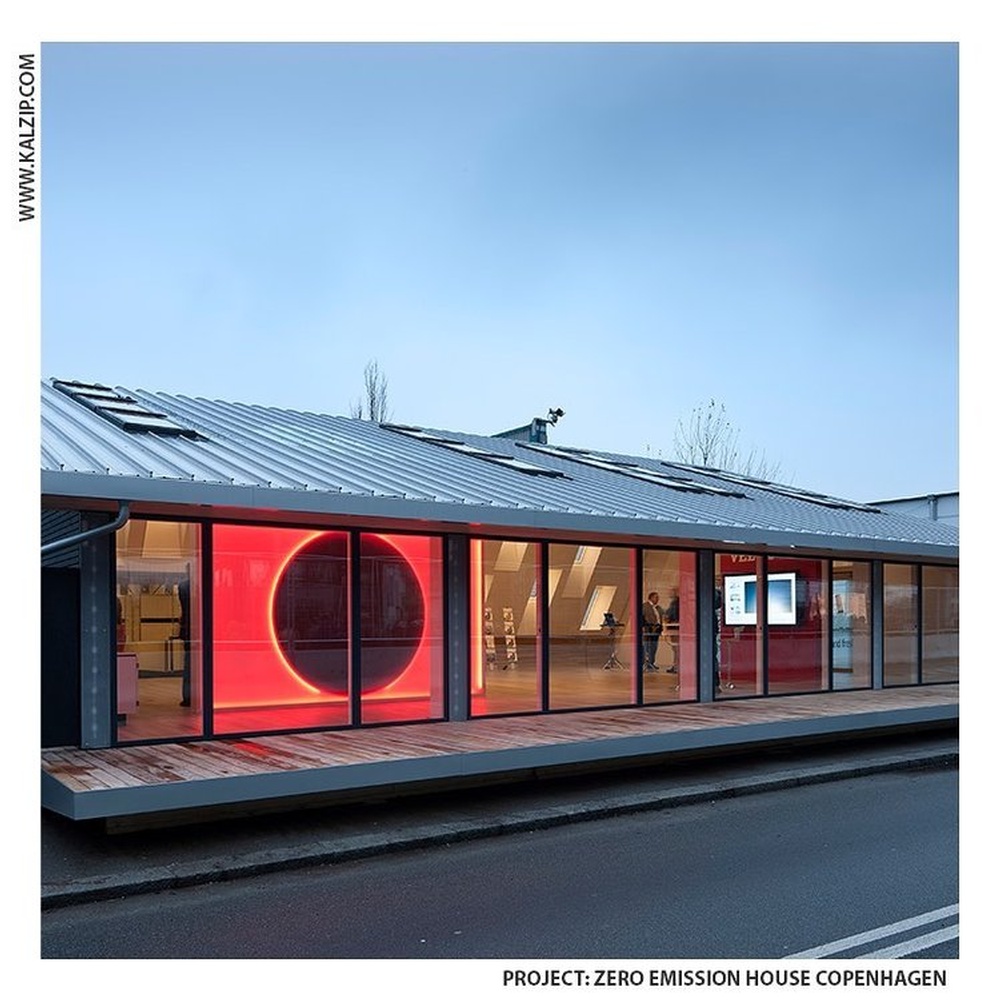

Such a symbol of carbon-neutral construction. Opened at COP15 in 2009, the Zero Emission House in Copenhagen is a perfect…

Click Here To Read The Full Article

Winnipeg’s metals division took on the task of cladding the new home of the Winnipeg Blue Bombers, which consisted of…

Click Here To Read The Full Article

Project Summary Architect: ZAS Architects + Interiors Location: Toronto, ON Facade Manufacturer: Alpolic and Alumicor Curtain Wall, Windows & Glazing Facade Consultant: CFMS Consulting…

Click Here To Read The Full Article

Project Summary Architect: Pelli Clarke Pelli Architects, Stantec Client: City of Winnipeg Location: Winnipeg, Manitoba LEED: Silver Certified Completion: Oct 2011 Award: 2015 Award of Merit…

Click Here To Read The Full Article

While the world has been significantly impacted by a pandemic, developers of the $1.66-billion MSG Sphere in Las Vegas continue…

Click Here To Read The Full Article

This is the Free-Form Aluminum Roof on 407 TTC Subway Station by AECOM & Aedas. To achieve this beautiful design, Kalzip…

Click Here To Read The Full Article